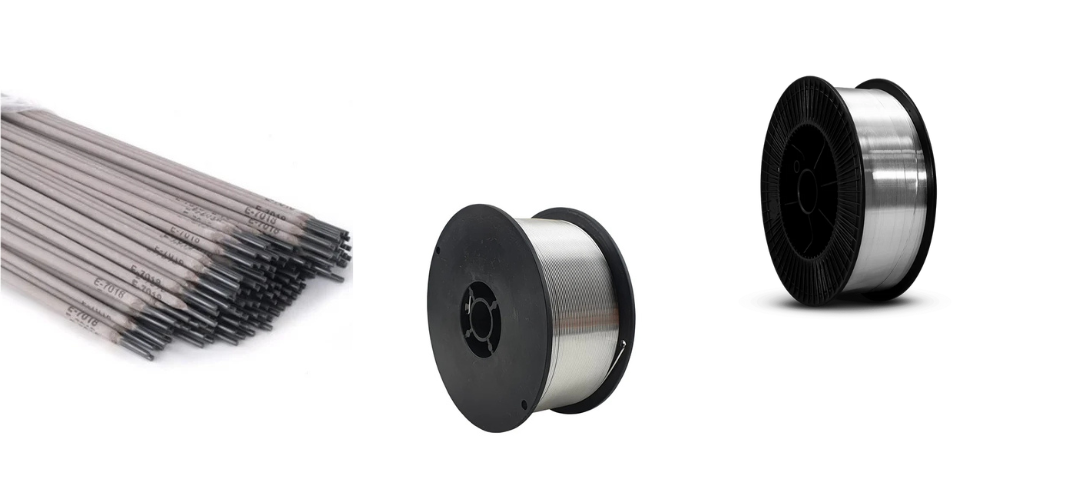

Welding Electrodes

Welding Electrodes are essential consumables in the welding process, serving as

the filler material that joins two metals together. They are carefully engineered to provide

strong, reliable, and durable welds while ensuring smooth arc stability and minimal spatter.

Depending on the type of coating and core material, welding electrodes are suitable for a

wide range of metals and applications, from construction and fabrication to shipbuilding and

heavy engineering.

There are different categories of welding electrodes, such as consumable electrodes (used in

Shielded Metal Arc Welding and Gas Metal Arc Welding) and non-consumable electrodes (used in

Tungsten Inert Gas welding). Consumable electrodes melt during welding to deposit filler

material, while non-consumable ones create an arc without being consumed. Each type is

designed to meet specific requirements for strength, conductivity, corrosion resistance, and

ease of use.

Stainless steel, mild steel, and special alloy electrodes are widely used across industries

to ensure welds can withstand mechanical stress, corrosion, and high temperatures. With

advances in manufacturing technology, modern welding electrodes provide superior

performance, consistent quality, and compliance with international standards, making them

indispensable in both industrial and commercial applications.

Available Welding Electrodes Types

- Stainless Steel Mig Welding Wire – High-quality stainless steel MIG welding wire designed for smooth feeding, consistent arc stability, and strong, clean welds, making it ideal for industrial and fabrication applications.

- 309L Mig Wire – Corrosion-resistant 309L MIG wire, specially formulated for welding dissimilar steels and stainless steels, ensuring durable and crack-resistant joints in challenging environments.

- 308L Filler Rod – Premium 308L stainless steel filler rod used in TIG welding, offering excellent resistance to corrosion and oxidation while providing strong, reliable welds on stainless steel materials.

- 316L Tig Rod – Superior quality 316L TIG welding rod engineered for excellent resistance to pitting and crevice corrosion, especially in chloride environments, making it perfect for marine and chemical industries.

- Stainless Steel Filler Rod For Tig Welding 304L – High-performance 304L stainless steel TIG filler rod designed for producing clean welds with low carbon content, reducing the risk of carbide precipitation and ensuring long-lasting strength.

- Tig Welding Rod For 304 Stainless Steel – Specialized TIG welding rod developed for joining 304 stainless steel, delivering excellent mechanical properties and superior resistance to corrosion and heat.

- 308LSI Stainless Steel Wire – Advanced 308LSi stainless steel wire with higher silicon content for improved fluidity, smooth bead appearance, and enhanced welding performance on stainless steel components.

- Er5356 Aluminium Filler Wire – Strong and corrosion-resistant ER5356 aluminum filler wire, widely used for welding aluminum alloys in automotive, marine, and structural applications.

- Aluminium Mig Welding Wire – High-quality aluminum MIG welding wire offering smooth feeding, low spatter, and durable welds, making it suitable for lightweight structures and fabrication projects.

- 304 Stainless Welding Wire – Reliable 304 stainless steel welding wire known for its versatility, corrosion resistance, and ability to produce strong welds in industrial, construction, and manufacturing applications.

- E308 Welding Rod – Versatile E308 welding rod designed for welding stainless steels such as 304 and 308, offering excellent resistance to heat and corrosion with smooth and stable welds.